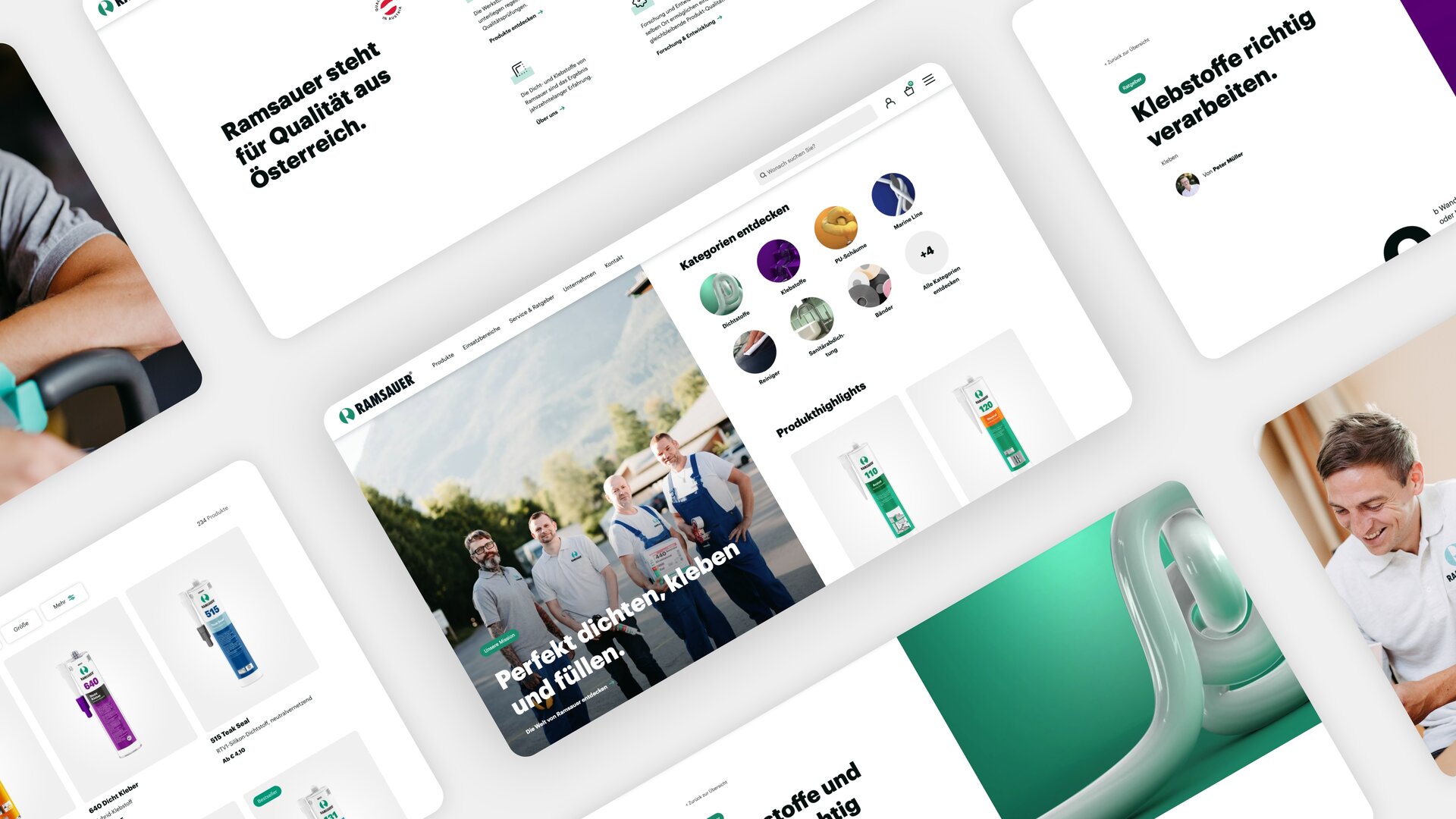

Digitalisation has been on everyone's lips since even before Covid-19 and is considered one of the most important elements for a company that is fit for the future. Ramsauer is implementing a comprehensive digital strategy and has not only digitalised and optimised production processes, but has also given its website and online shop a complete overhaul.

A new online presence for Ramsauer.

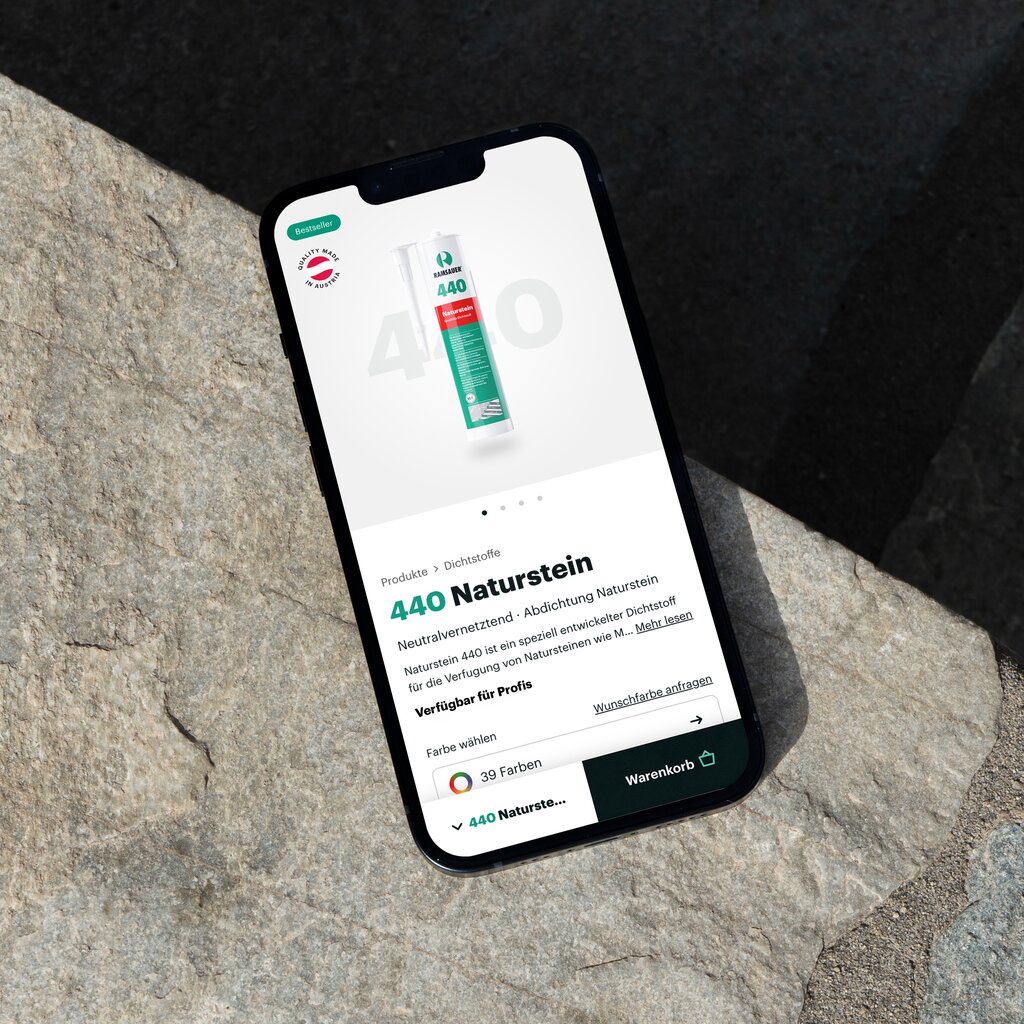

After months of development, the time has finally come: the new website is online and presents Ramsauer sealants and adhesives in a completely new manner. Ramsauer.eu now combines a unique online shop experience with interesting information about the company and its high-quality materials. Ramsauer is thus embarking on a completely new path because the entire online presence is no longer aimed solely at B2B customers, but at everyone. B2X is the keyword here.

From B2B to B2X – professional-grade materials for all.

With the objective of designing a B2X website, Ramsauer removes the boundaries between the individual target groups. The online presence is aimed at partners and business customers as well as hobby crafters. The shop was completely rebuilt to make this balancing act possible. From now on, every customer can order sealants and adhesives in an uncomplicated manner via ramsauer.eu. The stock levels are synchronised with the shop with the help of smart technology, which means that availability can be displayed in real time. The entire ordering process can be accessed in the Ramsauer customer portal.

In addition to the products, the Ramsauer website provides important information material as well as valuable application instructions in a separate How-tos section. The technical data sheets and IVD instruction sheets are also made available digitally and can be accessed anytime and from anywhere. Online tools – such as the practical sealant calculator – round off the digital Ramsauer experience.

Cutting-edge material production.

High-quality sealants and adhesives require continuous improvement of the production processes. For this purpose, Ramsauer has installed an innovative MES (Manufacturing Execution System) in production. The software digitally links the ERP system with the planning and production level. In addition to the automated tank storage at Ramsauer, all machine data is recorded and can flow into optimised detailed planning. In this way, the entire production can be controlled in real time. The introduction of the MES saves valuable resources such as raw materials and energy through shortened machine running times or working time.